AVOCADO OIL PROCESSING

Harvest Berry Limited is also involved in the processing, refining and sale of top quality, pure Avocado oil to various markets. This fruit contains 7-30% oil, depending upon the species/variety, and it is extracted by the cold pressing method or by solvent extraction. Hass and Fuerte are the most commonly used varieties for the extraction of avocado oil. Other avocado varieties include Reed, Bacon, and other regional varieties.

In Kenya, the most common type used for is Hass and Fuerte which is widely grown.

Nutritional value of Avocado oil

As avocado oil’s nutrient profile boasts of higher content of beneficial fatty acids, the health-conscious population, especially those who are battling obesity problems become the major consumer base of avocado oil. Avocado oil is positioned in the market as an immediate healthier alternative to olive oil, and an alternative to other cooking and dressing oils.

Among other benefits, avocado oil helps the body in:

a) Lower cholesterol

b) Lower blood pressure

c) Natural detox

d) Fights and prevents cancer

e) Treats skin damage and irritation

f) Stimulates weight loss

g) Helps in hair growth and boos nutritional absorption.

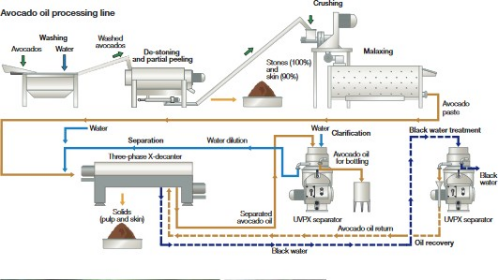

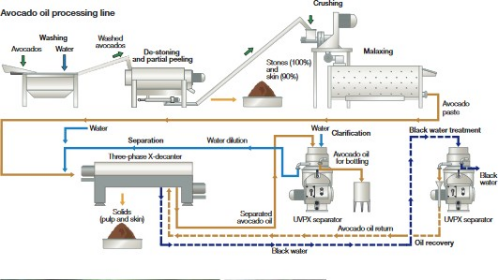

We use centrifuge system in our avocado oil production plant. The configuration of this system is as follows:

Fruit Reception

• Offloading of Fruits from the farms is done, whereby fruits are changed from plastic crates to wooden bins.

• Fruits are inspected for any external damage as random sampling of DM (Dry matter) test is done.

• Fruits are Weighed and given a Traceability code before transferring to the

Cool stores.

• Fruits are stored in the coolstores at 6 degrees for the first 2 days, (Aim is to harmonize the temperatures of the fruits since they come from different regions hence different climate)

• From the 3rd day to the targeted day of processing, you increase the temperatures to a maximum of 22 degrees.

• At this stage ensure the fans are on for adequate air circulation.

• Fruits start ripening, as Ethylene gas monitoring and room temperatures tests are done.

• Fruit firmness test is done to ensure that fruits are ready for sorting.

Fruit Washing

• Effective removal of leaves, dirt, stones, etc. is essential for ensuring the hygienic conditions required for high-quality Avocado oil

• Gentle but effective washing before oil extraction also helps protect the machinery from excessive wear and tear, and to safeguard the integrity of the fruit

• Whole fruits are washed in a two stage washing system

• First washing is performed by immersion in order to remove dust from the surface of the fruits.

• The soft water flow generated by a jet system gathers fruits by a bucket elevator, which has two functions, ie washing fruits a second time by showering them & working as a water dripping.

• The elevator takes the fruits into the destoning machine.

Destoning

• On the destoner the fruits stone and skin is removed where by 35% of the fruit is the stones & skin.

• The specially aligned rotor blades destoner hurl the fruit against the internal wall of the sieve, while an ideal conversation of the cores is guaranteed. The flesh of the fruit is pressed against the holes of the sieve.

• The core remains in the rotor chamber and is tangentially discharged at the rear end wall of the machine, after all fruit flesh has been thoroughly removed & pumped into the Crusher.

Disk Crusher

• The Disc Crusher further refines the pulp.

• The Disc crusher is important to cut the filaments remains on the paste and, at the same time, to minimize the emulsion.

• This approach enables to optimize oil extraction.

Malaxer

• The work of the malaxer is Heating, retention and mixing (malaxing).

• Crucial steps in the Avocado oil extraction process that, together with the amount of oxygen in contact with the paste, play a major role in determining the quality and quantity of the oil. The combination of time and temperature affects the enzymatic activity responsible for the release of the oil.

• The pulp malaxers for 90 minutes and the temperature should be below 50°C for Extra Virgin oil.

• In the malaxers small oil drops are released during pulp mixing & merge into large drops that can be easily separated by centrifugal extraction.

• After the pulp has malaxed for 90 minutes the pulp is pumped to a Decanter Centrifuge.

Decanter

• Oil extraction

• The separation of oil from solid and liquid phases is done using a decanter centrifuge.

• This device exploits the centripetal acceleration to separate continuously a mixture of particulate solids and liquids with phases having different densities.

• The solid waste then moves with a conveyor into a waste collection.

• The oil phase and the water phase are collected separately under the decanter. The oil phase is pumped out to a vertical purifier centrifuge (Separator), while the water phase is pumped out to a vertical concentrator centrifuge (Separator).

Separator

• The work of the separator is to separate two intermixed and mutually insoluble liquid phases of different densities.

• With the separated-off solids being discharged intermittently, they are used to clarify/polish oil (two- and three phase separation) and to recover oil from black water (three-phase).

• Water in the oil is extracted to avoid oil oxidation.

• On the Separator oil testing is done, parameters of FFA (Free fatty acid) & PV (Peroxyl Value) are taken to ensure that the oil is good for human consumption.

• The Separator is the last machine in the set of machines of Avocado oil extraction.

Flowmeter

• The work of the Flow meter is measuring the amount of oil extracted.

Sparging Unit

• In the sparging unit the oil is sparged (applying a stream of very small bubbles through the oil) with oxygen free nitrogen to remove any dissolved oxygen.

• During storage, a blanket of nitrogen or inert gas, should be used in the top of the tanks

• The oxidation of lipids can occur via photooxidation mechanisms when the light and a photosensitizer are present.

• The oil passes through the sparging unit as it is pumped into a cooling tank.

Receiving tanks

• Oil is received on receiving tanks as tests for FFA, PV & Pesticides are done.

• The purpose of this tank is to make sure that any contaminated oil is put into a separate tank/quarantine before being transferred into a cooling tank.

Cooling tanks

• In oil storage, increase in temperatures will result in chlorophyll breakdown and increased rates of oxidation reactions, hence maintenance of cool ambient storage conditions is important.

• The oil is pumped into a cooling tank with a controlled temperature of 15°C for 48 hours.

• After 48 hours some wax will have settled at the bottom of the tank, and this can be drawn manually before being transferred to the settling tank.

Settling tanks

• Oil is transferred to settling tanks, these tanks are specifically for storage.

• In the process, dewaxing is done manually until the oil clear and ready for dispatch.

• Before dispatch final tests are done to the oil in the tank to ascertain that the oil has the parameters required by the customer and is free from any contamination.

Boiler

• The work of the boiler is to heat processing water.

• Boilers may vary from Fuel, Gas or electrical.

• Processing water should be between 50 deg to 60 deg at the Malaxers, Decanter and Seperator.

• The processing water should be soft and portable so as to avoid scaling. scaling occurs when water has high levels of minerals like calcium carbonate.

Water storage

• There should be a relative constant water supply and storage to enhance sufficient processing water.

• The water should be soft and portable.

• All processing water should go through a water filtration system so as to ensure the processing water is free from physical, chemical, biological or radiological substance or matter.

Ripening

Ripening shall be done in ideal ripening environment as per the recommended parameters, with dedicated staff, frequent monitoring and strict reconciliation between the received and processed quantities.

Use of ICT

We use a comprehensive and inclusively developed ICT platform in sourcing, aggregation, transportation, receiving, ripening, export and processing of the avocados. The platform is also used to pay farmers within 24 hours of collection and to monitor farmer accounts.